The integration of AI in manufacturing facilitates in the automation of operational process, cost reduction and an efficient inventory management.

Updated 15 January 2024

VP – Pre Sales at Appventurez

Artificial intelligence (AI) is one of the new, potent technologies that is widely used for reducing human workload in practically every industrial process. AI and machine learning (ML) models are now being extensively implemented by many traditional manufacturing organizations in order to save time and money.

Despite the fact that most industrial processes have been studied in depth for decades, recent advances in artificial intelligence, particularly machine learning, have opened up new avenues for further improvement. The integration of AI in manufacturing industry can help improving the situation by replacing the current average sub-optimal values with accurate values.

AI app development also allows businesses to create a model that incorporates data from a variety of sources, including starting material composition, raw material quality, and sensor readings from a plethora of devices. This blog further explores the role of artificial intelligence technology in the manufacturing and how it is playing a crucial role in transforming the industry.

The role of AI in manufacturing is primarily concerned with reducing downtime and ensuring that production lines remain operational.

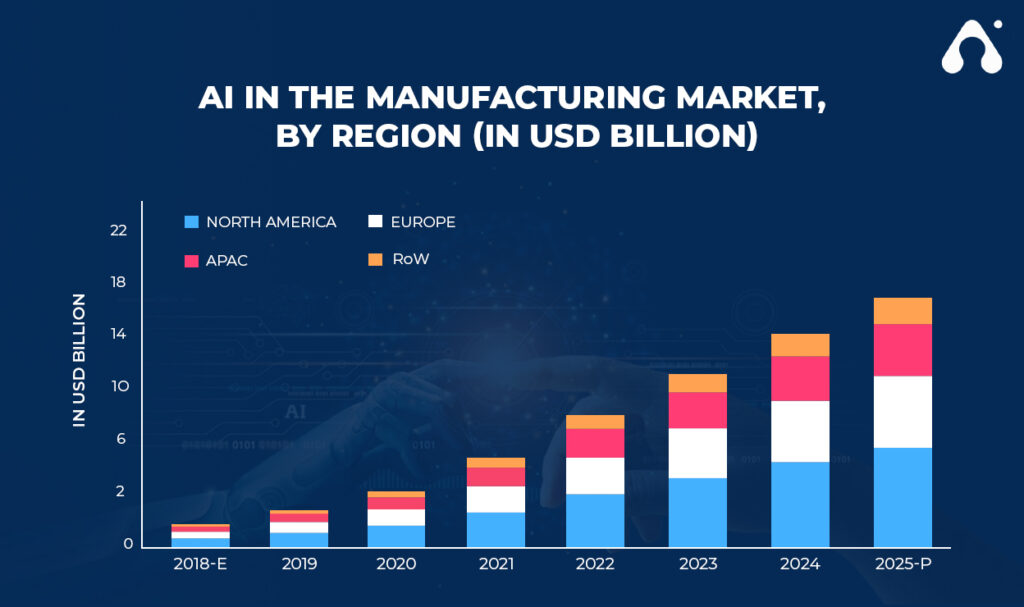

In 2018, the collaborated market of manufacturing and artificial intelligence was valued at over USD 1 billion, and it is expected to increase at a 40% CAGR from 2020 to 2025 – (Global Market Insight). The usage of artificial intelligence in the manufacturing industry is growing because of increased venture capital investments in AI.

When a machine learning model detects abnormalities during a certain activity or other trends that signal a machine problem, it employs predictive intelligence to assess whether human intervention is necessary. The use of AI in manufacturing industry models may help in concluding when a manufacturing line has to be stopped or run at a lesser capacity. This process could be followed until replacement components arrive, based on the cause of the odd pattern.

Leveraging artificial intelligence in the manufacturing industry can also help in making data-driven choices that save them hundreds of thousands of dollars in production and minimize plant downtime.

Artificial intelligence in development may be used to forecast when replacement parts are required. This capability lowers industrial machinery downtime and prevents costly components from stacking up in inventory. By accumulating vast volumes of data, machine learning algorithms can detect trans patterns that may signal a possible part failure. This research may be taken a step further, and plant maintenance and repairs can be scheduled based on the models’ predictions at the most efficient period.

Artificial Intelligence improves with time, it may also aid the industrial business. The use of machine learning development services facilitates the manufacturing businesses in developing models that are better equipped to forecast problems as they continue to evaluate data relevant to the business and manufacturing process.

Manufacturing is one of the most dangerous industries to work in, with over 3,000 serious injuries and nine fatalities per year. With the help of artificial intelligence, the robots can assist the firms in high-risk tasks in reducing unintended mishaps.

Manufacturers may save money by using AI technology as a service in a variety of ways:

With AI in manufacturing industry, manufacturers can collect vast amounts of data and transition to real-time analytics thanks to IoT devices. This enables producers to gain insights faster and make operational, data-driven choices in real-time.

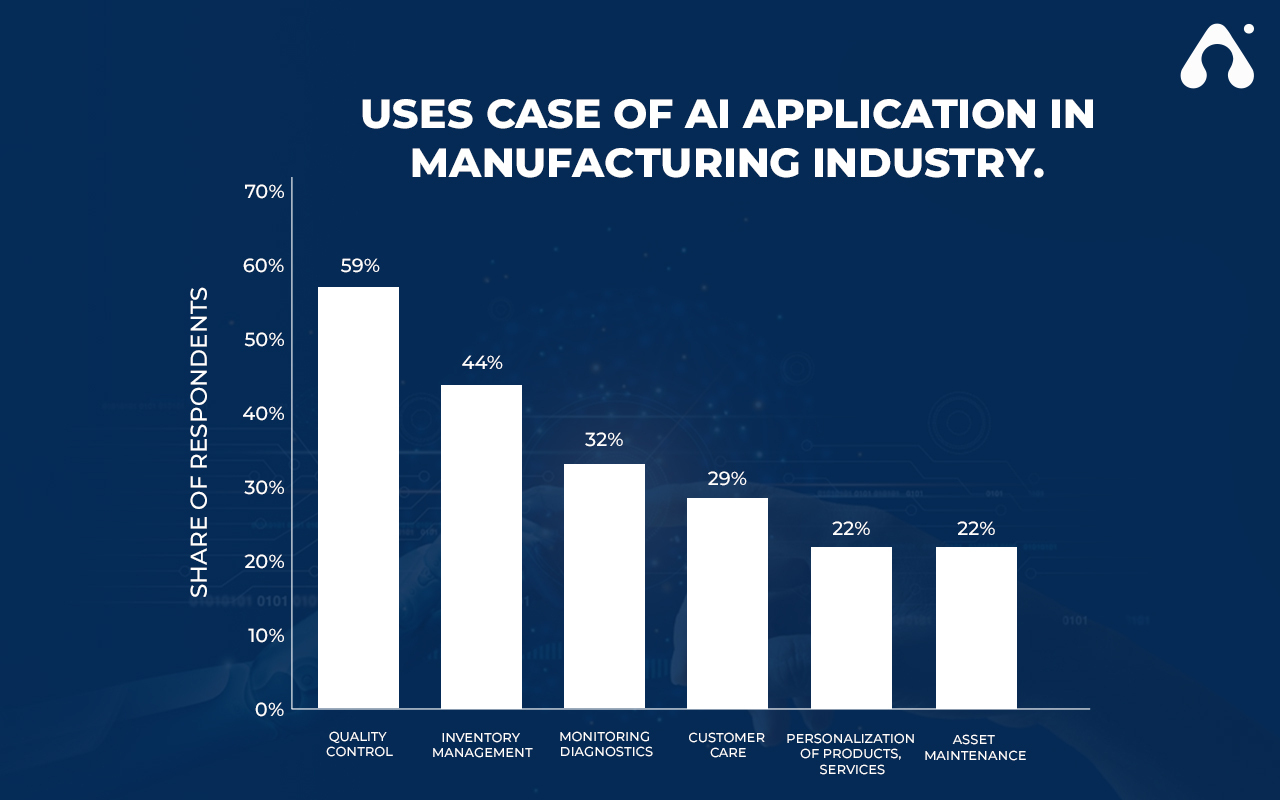

Enterprises are utilizing artificial intelligence in manufacturing to propel their business toward immense growth and advancements. Below are some of the popular AI in manufacturing examples and use cases that showcase the top-drawer advantages of this technology.

It is the most effective AI use case for industrial purposes often observed in the manufacturing domain. Internal equipment flaws are difficult to discover. Experts are often unable to spot problems in items just by monitoring their operation. AI & ML technologies will integrate, on the other hand, are capable of accomplishing this. Minor defects in equipment may be recognized quickly and easily using AI systems, tools, and applications.

As a result, AI in the industrial sector guarantees quality assurance. Machine productivity is monitored, performance is tracked, problems are found, productivity is improved, and maintenance expenses are reduced using smart AI solutions. That is why the majority of industrial organizations opt to collaborate with an AI app development company to automate the manufacturing process.

Machine learning algorithms are used in generative design to emulate an engineer’s approach to design. Designers or engineers enter design parameters into generative design software (such as materials, size, weight, strength, production processes, and cost limits), and the software generates all conceivable outcomes based on those factors. Manufacturers & businesses need AI to swiftly produce hundreds of design choices for a single product using this technology.

Extreme raw material price volatility has long been a problem for producers. To be competitive in the market, businesses must adjust to the fluctuating price of raw resources. Material costs can be predicted more correctly with the integration of AI in manufacturing industry than by people, as it presents the exact picture which also helps in the final budget estimation.

Industrial robots, often known as manufacturing robots, automate repetitive operations, reducing or eliminating human error, and allowing humans to focus on more productive aspects of the operation. Robots may be used in a variety of ways in plants. Since the late 1970s, industrial robots have been used in manufacturing companies.

An industrial robot can assess its own accuracy and performance and teach itself to improve with the inclusion of artificial intelligence in the manufacturing industry. Machine vision is a feature on some manufacturing robots that allows them to move precisely in complicated and unpredictable settings using machine learning as a service.

AI in manufacturing also facilitates edge analytics that extracts insights from data sets acquired by sensors on machines in a quick and decentralized manner. To minimize time to insight, manufacturers gather and evaluate data on the fly. In manufacturing, there are three applications for edge analytics:

The preservation of a desired degree of quality in a service or product is known as quality assurance. AI in manufacturing facilitates assembly lines which are the networks that are data-driven, networked, and self-contained. These assembly lines are guided by a set of parameters and algorithms that help them generate the finest possible final products. Because most flaws are apparent, AI systems can identify variations from expected outputs using machine vision technologies.

When a final output is of poorer quality than planned, AI systems send out a warning to users, allowing them to respond and make changes.

Machine learning systems, which are adept at demand forecasting and supply planning, can help to enhance inventory planning operations. The use of artificial intelligence in the manufacturing industry with AI-powered demand forecasting technologies outperforms traditional approaches (ARIMA, exponential smoothing, etc.) used by engineers in manufacturing plants.

These solutions help firms to better manage inventory levels, reducing the likelihood of cash-in-stock and out-of-stock events.

Automation is nothing new to manufacturers. For more than 50 years, the manufacturing sector has focused on creating better goods – primarily through automating operations, cutting operating costs, and improving quality.

However, the great majority of industrial firms must overcome a number of other roadblocks to digital transformation trends and AI activities, including:

Experienced data scientists and AI workers are rare and difficult to find in organizations across all sectors. Data scientists, machine learning engineers, software architects, BI analysts, and SMEs are all needed for AI initiatives. Many firms lack these resources and cannot afford to dedicate them to a single data science project. It’s considerably more difficult to grow to deliver on time when you have numerous data-science projects to complete.

This is especially true in manufacturing, a field that many young data scientists see as dull, repetitious, and uninteresting.

Manufacturing plants frequently include a diverse range of equipment, tools, and production systems that employ a variety of technologies, some of which may be running on obsolete software that is incompatible with the rest of the system. Plant engineers must select the optimum method to link their equipment and systems, as well as which sensors or convertors to install, in the lack of standards and common frameworks.

This is becoming more significant in manufacturing applications, such as quality control and following client delivery deadlines. Decisions must frequently be implemented right away. Such quick decision-making necessitates streaming analytics and real-time prediction technologies that allow producers to move quickly and avoid unfavorable outcomes.

What will artificial intelligence’s involvement in manufacturing look like in the future? There are many different perspectives of AI in manufacturing industry, some of which come from science fiction and others which are expansions of existing technologies. The most visible change will be a stronger emphasis on data collecting.

Top Artificial intelligence trends in technology and techniques used in the industrial industry can only do so much on their own. As the popularity, use, and efficacy of Industrial Internet of Things devices grow, more data may be collected that AI platforms can utilize to better differentiate manufacturing activities.

However, as the role of AI in manufacturing progresses, we may witness the advent of fully automated factories, product designs created automatically with little to no human oversight, and other innovations. But for that, we need to constantly innovate, else it will become challenging to get to this position.

All it takes is a thought. It might be a technology unification of the application of technology to a new use case. The role of AI in business is the breakthroughs that change the manufacturing market environment and help organizations stand out.

In the realm of manufacturing, staying competitive and relevant necessitates the adept utilization of emerging technologies and the continual enhancement of processes, such as AI and Machine Learning. Manufacturers find Artificial Intelligence to be a particularly potent and efficient platform, allowing them to make proactive decisions and position themselves confidently for the future. An AI app development company can play a pivotal role in enabling AI in manufacturing businesses to harness the full potential of these advanced technologies.

If you are also planning to take advantage of AI development services for your manufacturing company, and do not know how to choose an AI app development company, you can consult with Appventurez, an AI development company that will provide you with complete information.

Q. How does artificial intelligence affect the manufacturing industry?

AI-PowerEdge manufacturing solutions can help manufacturers automate processes, allowing them to create smart operations that cut costs and downtime. To estimate product demand and price efficiently, AI systems employ predictive analysis and integrate it with human intelligence.

Q. How is artificial intelligence transforming manufacturing?

Artificial intelligence can process data from sensors, equipment, and people, and then apply it to algorithms to improve operations or accomplish lights-out manufacturing.

Q. How does AI help in heavy industries?

AI-powered systems can see patterns and trends, identify inefficiencies, and forecast future outcomes based on prior data, allowing for better decision-making. As a result, they have the potential to benefit a variety of sectors, particularly heavy industry.

Elevate your journey and empower your choices with our insightful guidance.

VP – Pre Sales at Appventurez

Anand specializes in sales and business development as its VP - Sales and Presales. He supervises the pre-sales process by upscaling on establishing client relationships. He skillfully deploys instruments such as cloud computing, automation, data centers, information storage, and analytics to evaluate clients’ business activities.

You’re just one step away from turning your idea into a global product.

Everything begins with a simple conversation.