Automation in food industry in manufacturing, processing, packaging, maintaining safety standards, and waste management, can help upscale its revenue and boost its capacity.

Updated 24 January 2024

VP – Pre Sales at Appventurez

Automation in food industry aims at reinforcing aspects that are elemental to its sustenance but underachieving. Despite the industry being one of the largest, greater dependence on human labor to execute repetitive functionalities has deflated its economy. The ratio of production to demand is severely short. This, at times, disrupts the demand-and-supply chain causing inflation in foodgrain prices and food shortages.

An effective answer to this crisis is the incorporation of robotics and AI into the food industry. Several companies in food production have taken decisive steps in this direction. Various levels of functionalities, for instance, manufacturing, packaging, and delivery can be made efficient by constituting robotics in the food industry. On the other hand, the integration of AI development services can lead to the automation of processes that are performed manually, make production cost-effective, and minimize risks and errors.

A detailed analysis of the role of AI in the food industry is essential to understand the application of robotics and artificial intelligence comprehensively.

The food industry has undergone a paradigm shift in character due to upheaval in the consumer demand curve and rigid environmental regulations. There is pressing urgency to better food quality, meet the ever-rising demand, ensure food safety, and incorporate statutes on environmental issues like plastic ban, carbon emissions, etc. Companies have found a comprehensive solution to these challenges through robotics and automation in the food industry.

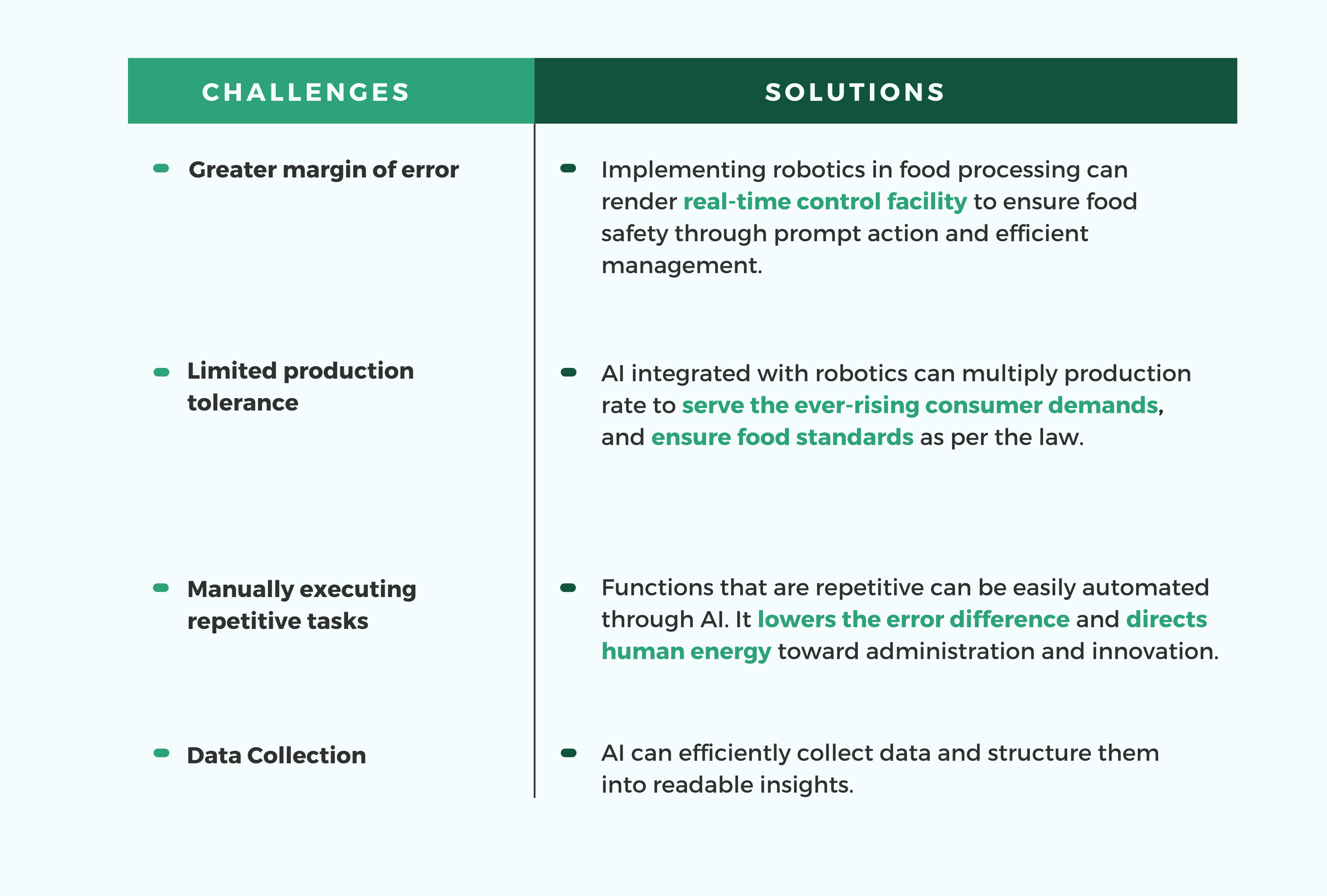

The following infographic outlines the challenges in the food industry and the solutions—

In nearly every sector of the economy, companies have invested in artificial intelligence services in the handling and management of a range of functionalities. In the food industry, the utility of AI is substantial. For instance, the use of pattern recognition in sorting food products, and data science in structuring random data can be advantageous. Deep learning in processing and packaging, and machine learning in revenue prediction can be deployed for better outcomes.

Trend forecasting is a method that enables decision-makers to take appropriate action based on predictive analysis further promoting automation in food industry. In the industry, ML-based algorithms can render detailed insights into the upcoming ups and downs. This can prove to be an excellent tool for anticipating customer preferences and keeping the trends under inspection.

Integrating trend forecasting in the food industry can provide impetus to companies in achieving their revenue targets. Manufacturers can make informed decisions as per the insights and make adjustments to their functioning to make profits with food data accordingly.

A remarkable food product is an amalgamation of consumer preferences, healthy character, and a sustainable process of manufacturing. By collecting insights from consumer trends, AI can lead to new product development.

AI-powered programs can form new recipes and design new products while enhancing the role of automation in food industry. It deploys computing, machine learning, and data analytics to make food products tastier and easier to cook. Cognitive abilities to cater to human requirements are also applied by AI chefs. A prominent example is Chef Watson by IBM who can be a great companion to chefs in the kitchen in examining dishes and suggesting recipes.

Packaging and shipping manufactured goods to the markets are two of the most crucial operations in the food industry. The process, however, is so monotonous and tiresome that the error quotient in the case of human involvement increases to detrimental levels. Thus, automation food industry can provide an effective solution for the packaging problem.

AI led food processing automation renders intelligent solutions employed through a variety of tools and approaches. These include laser and X-ray technologies, high-resolution infrared cameras, and spectroscopy. These technologies are utilized at the input channel to evaluate food commodities and sort out bad products through in-depth scanning and thorough examination. In comparison, traditional systems could only discriminate between good and bad items based on their appearance.

The deployment of AI-based systems in food packaging and product sorting has also several economic benefits. On one end, the cost of manual labor is cut, and only operational cost remains. On the other end, sanitation of impeccable standards through cleaning food processing equipment is assured. Furthermore, decision-making through predictive analysis and demand-supply chain management are also kept in balance.

AI-based systems and robotics can be sterilized and, therefore, are suitable for the food industry. It is due to this characteristic that the possibility of contamination in food products is reduced to zero. This in turn reduces the risk of foodborne diseases and food poisoning.

In several cases, food grains like wheat and pulses, and oilseeds like mustard and sesame are stored unpackaged in large godowns over longer periods without refrigeration. This is done to maintain a buffer stock to meet demands in extraordinary circumstances. However, these grains do get contaminated in humid conditions and lead to the development of various diseases and symptoms in humans.

The role of AI in food safety is to ensure such instances of errors do not occur. Additionally, as a solution, AI-based automation in food industry can measure and identify the contamination status of a food product efficiently. This is made possible by Next-Generation Sequencing or NGS.

NGS (Next-Generation Sequencing) is a method of sequencing that strengthens food safety and security through data collection, analysis, and extensive testing. It can measure contamination and prevent possible hazardous implications through genome examination.

EN (Electronic Noses) are electronic sensing devices that examine odors to determine food quality and food spoilage. The application of the device also consists of data acquisition and machine learning data analysis to identify degrees of falsification and read the manufacturing process.

It is estimated that a total of 17% of the food produced globally is wasted. Out of which, 7% is wasted in retail and services. The economic cost of that percentage is approximately USD 1 trillion per year!

These insights shed light on the inefficient management of food waste. Integration of AI and ML-based systems not only at the stage of manufacturing but at cultivation can enhance decision-making capacity and reduce instances of food waste.

All these methods would help in the overall reduction of food wastage by helping manufacturers in product management, assuring food safety, and reducing wastage.

Like every major industry vertical, the food industry has its massive supply chain system. The inclusion of AI in the supply chain has wide applicability, such as inventory management, demand forecasting, and more. The AI-led automation in food industry commences at the primary level of food crop cultivation and runs up to packaging and delivery. Let’s take a look at these steps in brief in the following section.

From the stage of sowing seeds to processing the harvest, cooking, adding the secret ingredients, packaging, and readying the product for delivery, the application of robotics that further leads to automation in food industry is nothing short of transformative. The advancement of technology in food industry can be facilitated through drones, armed bots, and heavy machinery programmed to carry out standard functionalities.

The utility widely aims to influence agriculture through smart farming and predictive analysis, and automating food packaging, food sorting, and storing. Let’s study these sections in brief.

Agriculture is an extensive activity. It includes various sub-sections like horticulture, floriculture, poultry farming, dairy farming, and so on. The indulgence of robotics in agriculture can automate and escalate routine tasks like plowing, soil monitoring, harvesting crops, measuring water levels, collecting milk and eggs, etc. Two-armed robots, drones, and heavy machinery can be programmed to promote automation in food industry and carry out tasks with efficiency.

Smart farming promotes the usage of technology to enable scientific methods of cultivation. For instance, drone technology can promote scientific farming by performing spatial analysis, moisture measurement, and field reconnaissance. This is made possible by the high-quality infrared camera setup installed on the drone. Similar is the case with machinery and other types of equipment operated in cultivation. These include tractors, harvesters, combines, planters, sprayers, and many more.

So far the implications of robotics in food delivery are concerned, drone technology is the major case in point. Drones are already used in the contactless delivery of goods and groceries. This is not only cost-effective on the operational level, but also saves time, reduces cost, and enhances efficiency by bringing automation in food industry. Drones are equipped with sensors and stereo-vision cameras to improve accessibility and avoid instances of accidents. The method is also sustainable as it replaces fuel exhaustion that is there in conventional methods of delivery.

The introduction of automation in food industry is not something new as the use of robotics is applied to the cookhouse. These are mostly in the form of two-armed robots that imitate human behavior and decision-making skills while cooking. The robots, thereafter, apply deep-learning mechanisms to develop their cookery skills. To enable imitation, the robots are equipped with sensors and optic cameras.

Recently, a UK-based company, Moley Robotics, constructed a robot inherently for cooking. The robot can skillfully add and mix ingredients, flip bread and stir meals, and clean utensils effectively.

The implementation of food processing robotics has already penetrated the industry. The efficacy applies in sorting, grinding, extrusion, agglomeration, mixing, etc. Another notable type of machinery that also brings automation in food industry includes an armed robot. These can be multi-joined or overhead-picking arm robots called ‘delta robots’.

For instance, a US-based startup, Zume, commissioned Vincento, a robot to perform smaller tasks in preparing pizzas, such as making the dough and baking the crust thoroughly and properly.

The involvement of robotics in food packaging in the industry, as per a survey conducted by the Association for Packaging and Processing Technologies, is estimated to be 94%. The implementation of automation in food industry has resulted in enhanced productivity with more than 100 products processed and packaged seamlessly.

Additionally, the integration of robotics in food packaging can enable a sustainable approach and ensure confirmation of the environmental regulations set by the government. Machinery can be geared with biodegradable and sustainable materials to use in packaging. Outside of these usages, robots can also box, sort, and warehouse products as programmed.

The yield on investment in robotics and AI in the food industry will be monumental over the next several years. It has been estimated that the market valuation for automation in food processing will reach $29.4 billion by 2027. The investment would be meant to escalate the rate of manufacturing products, automate packaging, ensure food safety, and manage food wastage. Larger implications of these provisions would be aimed at culminating manual labor and replacing direct human contact with a machine-embraced approach to carrying out tasks.

To summarize, the benefits of robotics and AI led automation in food industry would have lasting impacts on the following aspects —

There is no doubt that food automation, as has been emphasized throughout the article, presents extensive advantages. However, the industry could face financial stress and social adversaries through unemployment. The challenges of bringing automation in food industry are explained below.

The food industry is constantly losing value owing to undue dependence on conventional approaches. It has not only led to a widening margin of errors but also held back what the larger potential the industry is capable of accomplishing. With AI-powered machinery and automation in food industry, the future of the industry can become more advanced. Some instances include the following—

At Appventurez, we follow the advancing utility of AI-based technologies in various industry verticals with enthusiasm. The utility of automation through the integration of AI-based systems and robotics has been widely acknowledged by our team of developers. If you run a food business, perhaps a restaurant chain, or are planning on building an on-demand food delivery application to cater to the rising demands in your locality, a long-term collaboration to build a bespoke application is needed.

With the expertise amassed over the years through hundreds of mobile app development projects, we guarantee world-class product delivery that not only provides a seamless user experience but also fulfills its market requirements. For a two-way communication channel during the development process and an on-time delivery of the product, collaborate with Appventurez today!

Q. Why automation is important in the food industry?

The food industry needs automation to effectively address the challenges holding back its potential. AI-based systems and robotics in food industry can reduce the margin of error, elevate the rate of production, collect and structure data to render effective decision-making insights, and automate repetitive tasks.

Q. What is the role of robotics in the food industry?

Robotics in the food industry has wide applicability across segments, such as making cultivation efficient through mechanization, assorting raw material into manufactured goods through a systematic approach, ensuring safety standards, and better packaging.

Q. How is AI used in the food industry?

Implementation of AI-based solutions in the food industry is done in food processing and packaging, food safety and waste management, and revenue analysis.

Q. How do you automate a food business?

Automation of a food business can be done at several levels through robotics and AI technologies, such as manufacturing and packaging, food ordering, safety standardization, stock management, and cost-benefit analysis.

Elevate your journey and empower your choices with our insightful guidance.

VP – Pre Sales at Appventurez

Anand specializes in sales and business development as its VP - Sales and Presales. He supervises the pre-sales process by upscaling on establishing client relationships. He skillfully deploys instruments such as cloud computing, automation, data centers, information storage, and analytics to evaluate clients’ business activities.

You’re just one step away from turning your idea into a global product.

Everything begins with a simple conversation.