Machine Learning is rapidly becoming a critical component in the improvement of how manufacturers function within the supply chain.

Updated 11 March 2024

VP – Pre Sales at Appventurez

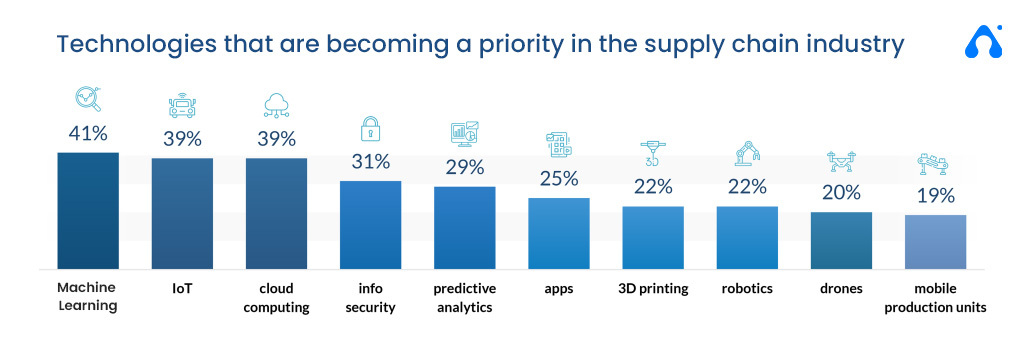

The primary goal of utilizing machine learning solutions in supply chain and logistics is to boost efficiency and production. The tech is leading to a new era of digitization in the industry and resulting in more sustainability, prompting every firm to question if digital transformation on this scale can help their individual supply chain business.

Since supply chain management is becoming more advanced with innovative solutions, machine learning drives the sustainability around it. This has caused every company to ponder whether digital transformation on this scale can help their particular supply chain business.

According to Allied Market Research, Logistics management has a lot of potential, since the logistics business is expected to be worth USD 15.5 trillion by 2027.

So, if you want to know what ML can achieve for your supply chain business, this blog is a perfect resource to dig deep. Let’s take a look at how ML affects the supply chain.

Machine learning (ML) is a branch of AI that enables machines to automatically learn from data and previous experiences while finding patterns to generate predictions with minimum human interaction.

Machine learning approaches allow computers to function independently without the need for explicit programming. ML apps are fed fresh data & learn, grow, evolve, and adapt on their own.

Using machine learning development in the supply chain extracts useful information from enormous amounts of data by using algorithms to recognize patterns and learn in an iterative process. Because of its powerful characteristics, it is the ideal solution for some of the most significant supply chain businesses that are facing crucial challenges.

Logistics companies are the backbone of every country’s economy. It’s difficult to conceive it without smart and efficient logistics and transportation. They are important in increasing commerce and guaranteeing seamless operations.

However, as technology evolves, consumer demand shifts, and law evolves, even the scaling logistics firms face difficulties. Let’s analyze them one by one:

Inventory management is essential for supply chain management because it enables businesses to cope with and respond to any unforeseen shortages. No supply chain organization would want to cease operations while starting a search for a new supplier. They wouldn’t want to overstock either since it starts to hurt their revenues.

Maintaining a dual check on quality and safety as well as the rising requirements to produce items on time to keep the supply chain assembly line rolling becomes a major problem for supply chain organizations. Issues and hazards in the supply chain can swiftly snowball across the whole supply chain, generating serious consequences.

The difficulties in logistics and supply chain caused by resource constraints are well documented. But the use of AI and machine learning in logistics and supply chains have made it much simpler to comprehend different aspects. After analyzing numerous aspects, algorithms that forecast demand and supply allow for early planning and appropriate stocking. In addition to providing fresh perspectives into many parts of the supply chain, ML has greatly simplified the administration of the inventory and team members.

Another issue that logistics companies confront is a severe shortage of supply chain expertise, which makes supplier relationship management inefficient and unproductive. Artificial intelligence and machine learning can provide helpful insights into supplier data and assist supply chain firms in making real-time choices.

The unanswered question is how to make your supply chain less subject to uncertainty.

The market dynamics of supply chain management have shifted dramatically as a result of variables such as shifting labor processes and fluctuating demand. The supply chain is no longer a linear deterministic process with a fixed step-by-step workflow. Rather, the supply chain has evolved into a nondeterministic workflow in which the sequence will be rearranged to improve the operation. Better supply chain management necessitates the use of automation.

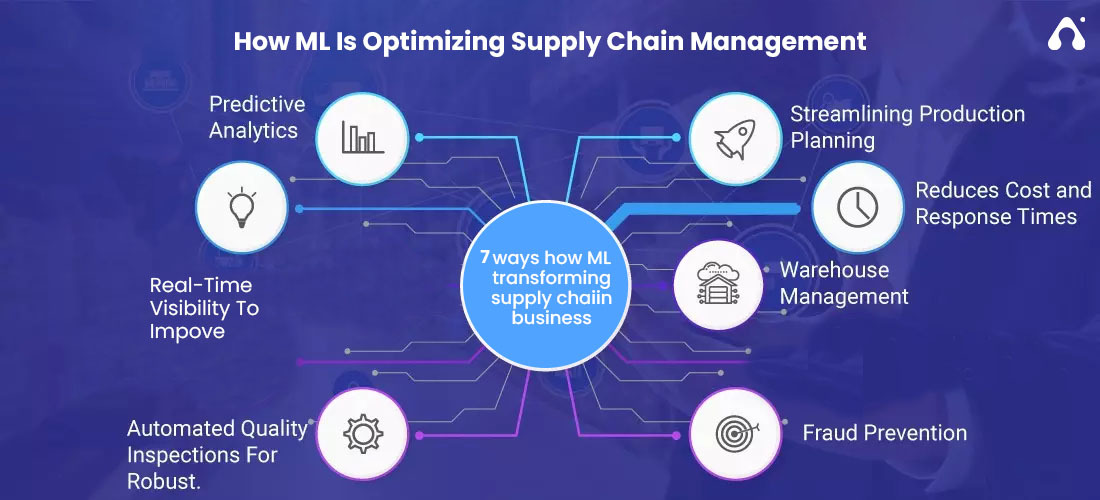

To begin, incorporating AI/ML into the supply chain process automates a variety of frequent and repetitive processes. Using an intelligent ML model will assist enterprises in selecting the best solutions and running their businesses more effectively.

In order to forecast demand supply requirements and balance the whole ecosystem, AI and ML solutions can evaluate the enormous quantity of data generated by warehouses, logistics, suppliers, and transportation systems.

Every stage of the process—from planning through purchasing, order processing, inventory management, logistics, and end-user delivery—can benefit from an ML-driven system as a service.

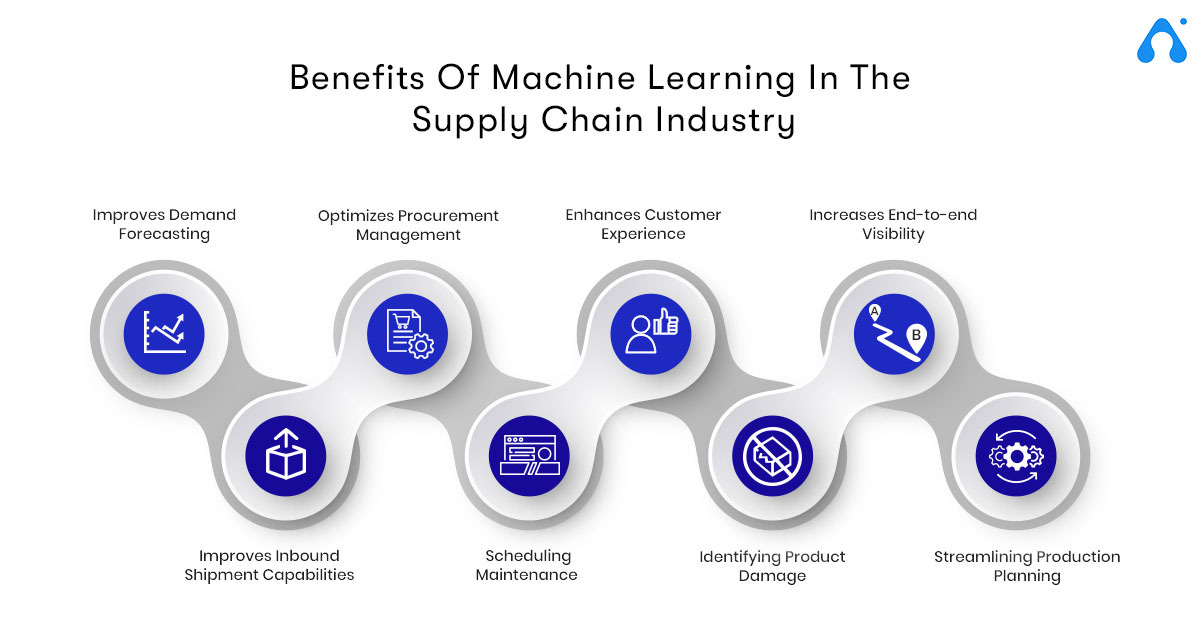

Machine learning guide helps to provide supply chain management with a number of advantages, such as:

In today’s era, technology assistance is needed in every step and function of the supply chain process.

In the supply chain, machine learning use cases assist retailers, suppliers, and distributors in driving the roadmap for digital transformation in logistics that are desperately required in the face of the pandemic.

Machine Learning adds unparalleled value to supply chain operations, ranging from cost savings through decreased operational overhead and risk mitigation to improved supply chain forecasts, faster delivery, and better customer service.

Machine learning also reveals where automation can provide the most substantial scale advantages. Let’s take a deeper look at all of the benefits that machine learning has to offer in supply chain business:

Since the supply chain is a sector that relies largely on data, machine learning has several uses in this sector. The top 6 use cases of machine learning in supply chain management are described here, which can assist the sector move toward efficiency and optimization.

Businesses gain profit from predictive analytics for demand forecasting by using machine learning models. The AI & ML algorithms are right for data analysis for spotting obscure trends in past demand data. In the supply chain machine learning will be used to identify problems before they affect corporate operations.

A strong supply chain forecasting system ensures that the company has the resources and knowledge necessary to address any threats or challenges as they arise. Additionally, the efficacy of the reaction rises in direct proportion to how quickly the company can address issues.

Manual quality inspections are regularly carried out at logistics hubs to check for transportation-related damage to packages or items.

The automated examination of manufacturing equipment faults and the use of machine learning in supply chain management for image recognition to check for damage are both made possible by machine learning-enabled technologies.

The benefit of these highly automated quality checks is a reduction in the likelihood of giving customers faulty or subpar goods.

A Statista poll identified visibility as a persistent problem for supply chain companies.

Deep analytics, IoT development, and real-time monitoring combined with machine learning techniques will significantly improve supply chain visibility.

Hence enabling businesses to change the consumer experience and achieve their goals for faster delivery. Machine learning models and workflows do this by evaluating historical data from several sources and identifying links between the processes throughout the supplier value chain.

Amazon’s use of machine learning techniques to provide its customers with an improved customer experience is a great illustration of this.

The complexity of production plans can be optimized with the use of machine learning. On the basis of production data that is already accessible, machine learning models and techniques can be used to train complex algorithms in a way that aids in the detection of potential inefficiencies and waste.

Furthermore, it is interesting how supply chain uses machine learning to make its environment more adaptive so that it can cope with disruptions in an efficient manner.

In order to manage on demand-to-supply mismatches, a growing number of B2C firms are using machine learning techniques. This reduces costs and improves customer experience.

Administrative and operational costs in the supply chain will be reduced by improving communication with a variety of logistics service providers and standardizing freight and storage operations.

The management of warehouses and inventories is often connected to effective supply chain planning.

With its models, techniques, and forecasting skills, machine learning in the supply chain will be able to handle the problem of under or overstocking and completely transform your warehouse management for the better.

Additionally, by utilizing AI and ML to develop data warehouses from scratch, you can review enormous datasets much more quickly and avoid human errors that are frequently made.

Machine learning as a service will be used for financial fraud detection by which it will enhance product quality and lower the risk of fraud by automating auditing and inspection procedures and performing real-time analysis of findings to discover abnormalities or deviations from anticipated patterns.

In addition, privileged credential misuse, one of the main reasons for breaches throughout the whole global supply chain development, will be prevented using machine learning algorithms.

Here are some of the top firms that are employing machine learning to improve supply chain management productivity:

It is one of the well-known supply chain leaders in the e-commerce sector and uses cutting-edge, ground-breaking technology powered by artificial intelligence and machine learning, such as automated warehousing and drone delivery.

Thanks to significant investments in sophisticated software systems, transportation, and storage, Amazon’s reliable supply chain has direct control over key areas including packaging, order processing, delivery, customer service, and reverse logistics.

A global leader in technology, mainly depends on predictive insights produced by machine learning and business intelligence in its supply chain system. Because of the company’s extensive product line, it creates a vast amount of data that must be linked centrally for predictive analysis and to increase operational effectiveness.

The organization has developed a completely integrated supply chain system using machine learning techniques, enabling them to collect and analyze data in real-time. Additionally, the organization’s strong supply chain makes use of proactive and early warning machine learning technologies to help with risk mitigation and speedy question resolution.

A well-known global powerhouse and a highly inventive tech firm, depends on a responsive and adaptable supply chain that can work across regions in an effortless manner. Alphabet’s supply chain is fully automated thanks to machine learning, artificial intelligence, and robots.

The market leader in consumer goods, has one of the most intricate supply networks and a broad range of products. For end-to-end product flow management, the organization makes exceptional use of machine learning approaches including advanced analytics and data application.

In the world of logistics, machine learning isn’t just a trendy word. It’s like having powerful tools that help companies save money, work more efficiently, and make their supply chains stronger and easier to see. These tools are becoming really important for companies that want to stay competitive. And if a company wants to use these tools, they might want to team up with a Machine Learning App Development Company to make it happen. Our Machine Learning team at Appventurez can assist you in gaining vital insights from your company data to maximize scalability and performance. We have a 10+team of ML developers that are working on a global project.

Q. How can machine learning be used to improve the business?

In order to reduce equipment malfunctions and boost earnings, firms utilize preventative maintenance with the aid of machine learning. Businesses utilize machine learning to use consumer data to create meaningful customer profiles, boost sales, and strengthen customer loyalty.

Q. How is AI used in supply chain management?

Utilize AI to produce data. Much of this process will be automated by a data insights platform with repeatable data pipelines to ingest, prepare, stage, and report on data, freeing up data scientists to focus on supply chain node insights.

Q. What are the benefits of machine learning?

Businesses always talk about the benefits of machine learning in the supply chain in terms of exponential gains and enhancements, regardless of where or how it is employed. Accelerated decision-making Machine learning enables speedy, even split-second, decision-making by enabling organizations to process and evaluate data more quickly than ever before.

Elevate your journey and empower your choices with our insightful guidance.

VP – Pre Sales at Appventurez

Anand specializes in sales and business development as its VP - Sales and Presales. He supervises the pre-sales process by upscaling on establishing client relationships. He skillfully deploys instruments such as cloud computing, automation, data centers, information storage, and analytics to evaluate clients’ business activities.

You’re just one step away from turning your idea into a global product.

Everything begins with a simple conversation.