Supply chain workers are using artificial intelligence (AI) to solve problems and improve global operations. Throughout supply chains, AI-enhanced technologies are being used to improve productivity, mitigate the effects of a global labor shortage, and uncover better, safer methods to transfer commodities from one location to another. AI in supply chain applications may be found […]

Updated 24 January 2024

VP – Pre Sales at Appventurez

Supply chain workers are using artificial intelligence (AI) to solve problems and improve global operations.

Throughout supply chains, AI-enhanced technologies are being used to improve productivity, mitigate the effects of a global labor shortage, and uncover better, safer methods to transfer commodities from one location to another. AI in supply chain applications may be found from the production floor to front-door delivery.

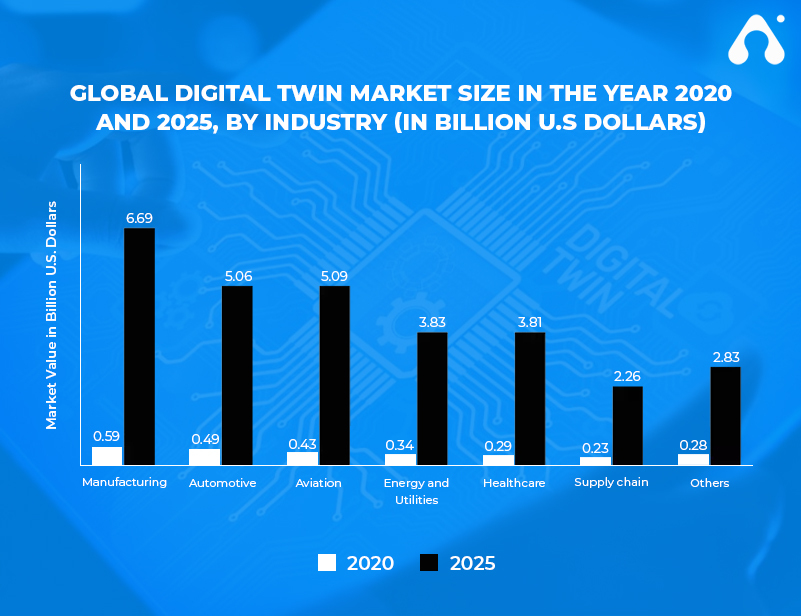

Companies can use digital twins to predict the possible effects of disruptions to detect and address vulnerabilities that could affect the organization. They may also be an effective tool for optimizing supply chain networks, procedures, and inventories.

As more organizations adopt digitization, the worldwide Industry 4.0 market is estimated to reach $210 billion by 2026. Digital twins & AI in the supply chain are some of the most important aspects of the manufacturing industry’s digital transformation since they boost efficiency and profitability while also improving customer experience. Besides this, digital twins and AI in the supply chain are all set to accomplish digital transformation across the entire industry.

A virtual simulation model of a genuine supply chain is used to assess supply chain dynamics and forecast process success in a supply chain digital twin. Real-time data and snapshots of planned and released work orders, sales orders, pending approvals, demand, and supply are beneficial with digital twin models for digital transformation. The information was acquired from a variety of sources, including:

The data that is used in digital twin technology is largely historical. However, digital twins can also operate with real-time data in some instances. Meaning of digital twins “A digital twin is a virtual representation of a physical item or activity that acts as its real-time digital equivalent”. The term “real-time data” refers to information that is supplied as soon as it is collected.

Analysts may use digital twins to better understand a supply chain’s behavior, foresee uncommon circumstances, and create an action plan to save costs and increase process efficiency.

A digital twin process can aid organizations in recognizing trends and simulating the effects of changes to various processes for:

What is the digital twin concept in supply chains? DT models are used to minimize business continuity and transformation risks before they arise through result prediction, therefore enhancing design testing of supply chain processes. Before the process is transformed, the models may be used to calculate benefits, savings, and possible ROI. For example, a company may create DT models to rethink its worldwide operations by simulating numerous scenarios including production, inventories, and product delivery.

DT allows supply chain firms to test and identify the optimal course of action in the event of an emergency, as well as try out alternative situations in a virtual environment, considerably enhancing organizational stability.

DT provides a perpetual, end-to-end view of processes and bottlenecks across the supply chain, facilitating more agile problem resolution with minor human intervention. By collecting data, digital twins help to identify potential weaknesses in all aspects of delivery. For example, a shipment digital twin will rely on data gathered from sensors that transmit updated data during shipment and can be analyzed to spot performance and bottlenecks during transportation and delivery trips.

While delivering products and services to end consumers, a digital twin can analyze how changes in demand and supply affect the supply chain’s physical locations and supporting systems. Digital twins in supply chain management to better arrange transportation resources by exploiting real-time data.

To avoid stock-outs and reduce total manufacturing and warehousing costs, a supply chain digital twin can input data from demand forecasting procedures. As a consequence, it handles both the “single-echelon” (optimizing inventory in a single warehouse) and the “multi-echelon” (optimizing inventory across many warehouses) challenges (optimizing inventory across the entire network).

According to McKinsey & Company, organizations will earn between $1.3 trillion and $2 trillion per year in economic value by incorporating AI in supply chain development. AI might contribute over $15.7 trillion to the global economy by 2030, according to PricewaterhouseCoopers.

Here are 5 ways in which AI in Supply Chain Disrupts the Industry:

AI is capable of processing massive amounts of data, which improves demand forecasting. It is now feasible to handle massive amounts of data collected – for example, by sensors – to display the actual world in real-time and make informed judgments.

AI provides insights that can help you increase your productivity.

Due to the automatic computation of superior solutions, AI dramatically boosts warehouse productivity, particularly for online merchants.

It is feasible to examine supply chain management’s performance and come up with new aspects that influence the same sector by using AI. AI uses the capabilities of diverse technologies such as reinforcement learning, unsupervised learning, and supervised learning to uncover the elements and challenges that impact AI in supply chain processes and performance.

Customer service is being redefined by chatbots: According to Accenture, bots can manage 80 percent of all consumer interactions. Customers and logistics suppliers may have a more personalized interaction using AI.

Artificial intelligence’s next big thing in the supply chain is autonomous cars. Although having self-driving trucks may take some time, the logistics business is increasingly utilizing high-tech driving to improve efficiency and safety. In terms of assisted braking, lane assist, and highway autopilot, this business is projected to undergo a major transformation.

The discipline of robotics must be mentioned in any discussion of Artificial Intelligence. They may appear to be a future notion, yet they are already present in the supply chain. According to Tractica Research, global warehouse and logistics robot sales will reach $22.4 billion by the end of 2022.

Products are stacked in numerous racks and passageways in what looks to be a chaotic manner in warehouses. When an order is received, the first available robot picks up the item that is kept closest to its place and transports it to the human packers at the end of the warehouse, which would mean needless travel and search times for a human picker.

Here are some of the benefits it offers in logistics and supply chains:

By availing of artificial intelligence app development services for your logistics and supply chain operations, you will save money because many of these tasks will be automated and carried out by AI systems. From customer service to the warehouse, automated intelligent processes can operate error-free for longer periods, lowering the number of mistakes and incidents in the workplace and allowing for considerable cost savings.

Chatbot development, which may improve customer service by giving a larger variety of capabilities such as enhancing search, delivering updates about new collections, and suggesting related goods, is another significant use of AI in the supply chain. With the help of chatbots in your business, you won’t have to educate your customer care employees, you’ll save money, and your clients will be able to search your product catalogs more correctly and without errors using these tools.

Artificial intelligence (AI) may help you increase customer delivery times by streamlining workloads and eliminating many of the bottlenecks that cause delays in all of your company’s processes. Furthermore, many of these integrated AI systems can determine the quickest, most cost-effective, and safest route to convey these goods, allowing logistics and supply chain procedures to be improved even further.

Automated AI-based systems can increase worker and material safety by ensuring better planning and effective warehouse management. Artificial intelligence in the retail industry can also assess workplace safety data and alert producers to any possible hazards. This enables manufacturers to respond fast and aggressively to keep warehouses safe and in compliance with safety regulations.

According to ongoing research, failure to make supply networks more robust to climate change might result in a slew of avoidable problems. Kevin Dooley, for example, is a principal scientist at The Sustainability Consortium and an Arizona State University faculty member.

NVIDIA is a good illustration of what can be done. Enterprise versions of NVIDIA digital twin technology have been employed by industry heavyweights such as Lockheed Martin, Ericsson, and others. Now, a project is underway to create a digital twin that will employ artificial intelligence and other modern technologies to forecast the consequences of climate change decades in advance.

Using AI & ML in a supply chain tool like this might allow users to concentrate their efforts on the outcomes that are most likely to create the greatest havoc. Then it will be easy to gain executive support and persuade individuals that there is no time to squander.

Creating a digital twin of a supply chain does not guarantee that the data it contains will be useful to consumers. However, including AI in its capabilities is a practical method to ensure that the tool only alerts users to truly important concerns that, if left untreated, might lead to supply chain troubles.

It may be obtained by constructing digital twins with AI capabilities. Artificial intelligence should not take the role of human-led decision-making. The technology, on the other hand, excels in detecting patterns in data that people might otherwise overlook. Instead of just informing a user that supply chain difficulties would occur, the AI component of a digital twin might suggest proactive strategies to avert them.

By analyzing evolving client preferences, and experiences, in supply chain business digital twins are already assisting businesses in staying ahead of digital disruption. For your firm, this information means faster product delivery, higher-quality data, and speedier development, among other things.

Other sophisticated technologies like NLP (Natural Language Processing), object visual identification, audio analytics, and signal processing are only a few of the aspects that go beyond human intuition when using Digital twin modeling.

Organizations may predict demand, boost accuracy, better understand buying cycles, estimate future warehouse capacity, and address difficult operational issues by leveraging Artificial Intelligence and Big Data on mobile app development to manage supply chain tasks, notably logistics.

The future of AI in supply chain advances is paving the way for a future in which AI-powered, self-driving cars will be deployed across supply networks. These platforms’ current data mining and analysis will continue to improve the cost and efficiency of an increasingly complex global supply chain.

This demonstrates that digital twin technology is about more than simply what we’re producing; it’s also about who we’re building for.

Appventurez is an AI development company that specializes in helping enterprises revolutionize their supply chain business through the power of technology and innovation. We believe in pushing organizations to become more agile and intuitive, in simple terms, and become more customer-centric.

With our suite of digital transformation solutions, including data modeling, legacy modernization, digital twin & AI development services, you can achieve tangible results. Connect with us to integrate AI into the supply chain and jumpstart your business.

Q. How AI could solve supply chain shortages?

AI can assist businesses in anticipating shortages and supply challenges and then responding with resilient solutions, such as rerouting the delivery of critical supplies when a port closes. This would necessitate having the data and the ability to model resilience responses.

Q. What is a digital twin in the supply chain?

A digital twin of a supply chain is a virtual simulation model of a genuine supply chain that may be used to assess supply chain dynamics and anticipate process success. Real-time data and snapshots of planned and released work orders, sales orders, pending approvals, demand, and supply improve DT models.

Q. Why is the digital twin important?

Digital twins have the potential to greatly improve data-driven decision-making processes in businesses. They are linked to their physical counterparts at the edge, and organizations utilize digital twins to understand the condition of physical assets, adapt to changes, optimize operations, and add value to systems.

Elevate your journey and empower your choices with our insightful guidance.

VP – Pre Sales at Appventurez

Anand specializes in sales and business development as its VP - Sales and Presales. He supervises the pre-sales process by upscaling on establishing client relationships. He skillfully deploys instruments such as cloud computing, automation, data centers, information storage, and analytics to evaluate clients’ business activities.

You’re just one step away from turning your idea into a global product.

Everything begins with a simple conversation.